|

|||

|

|

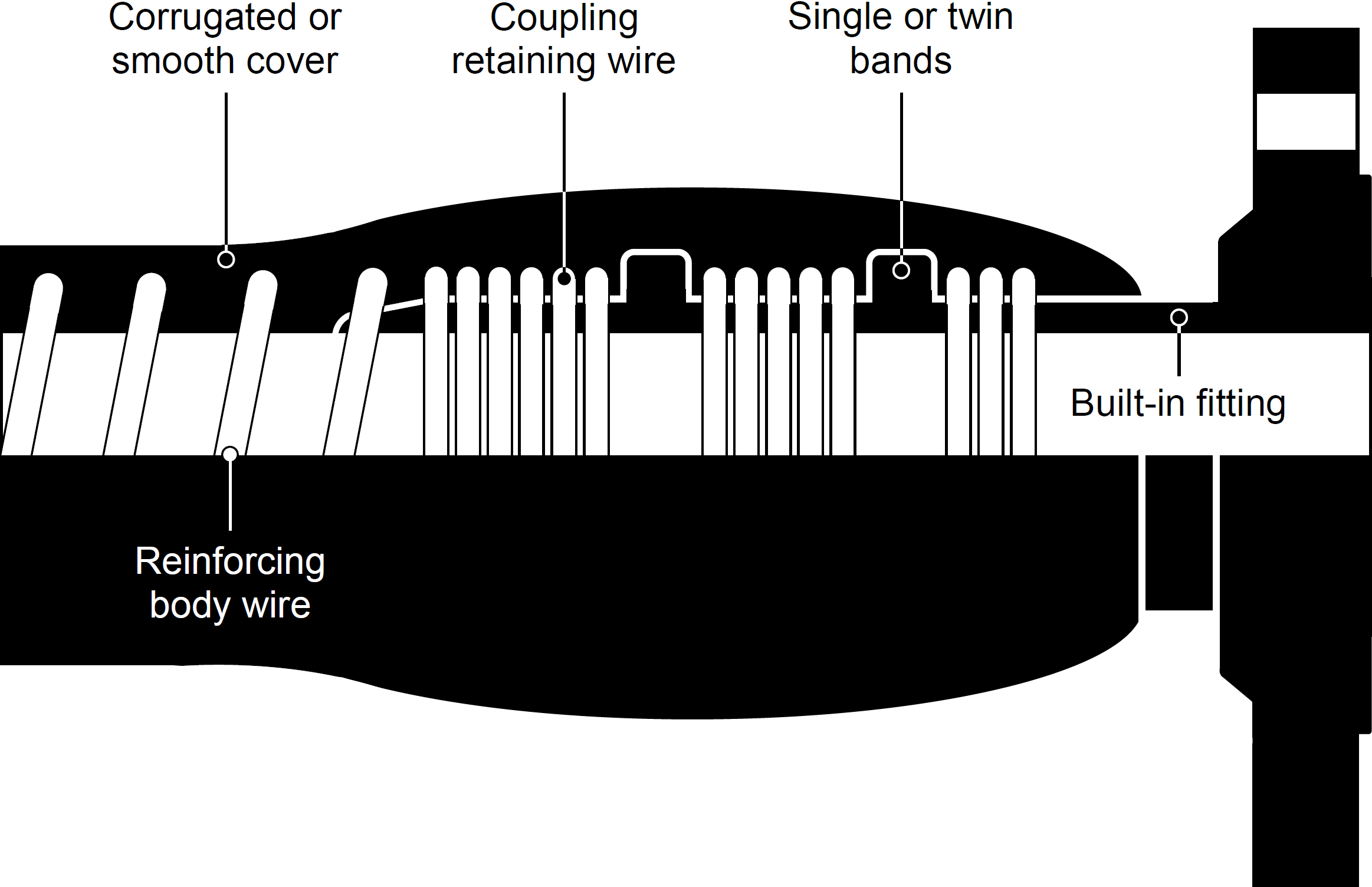

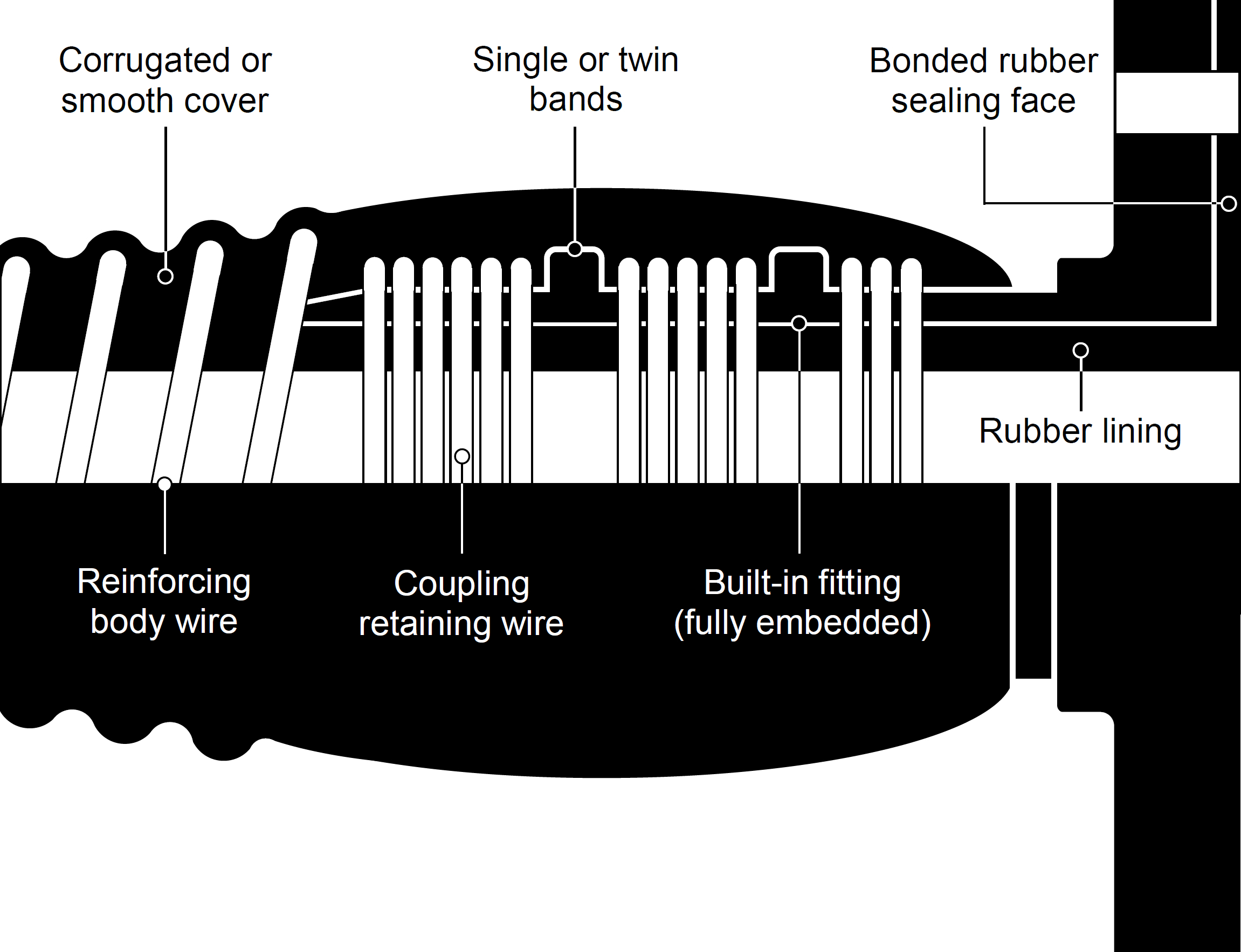

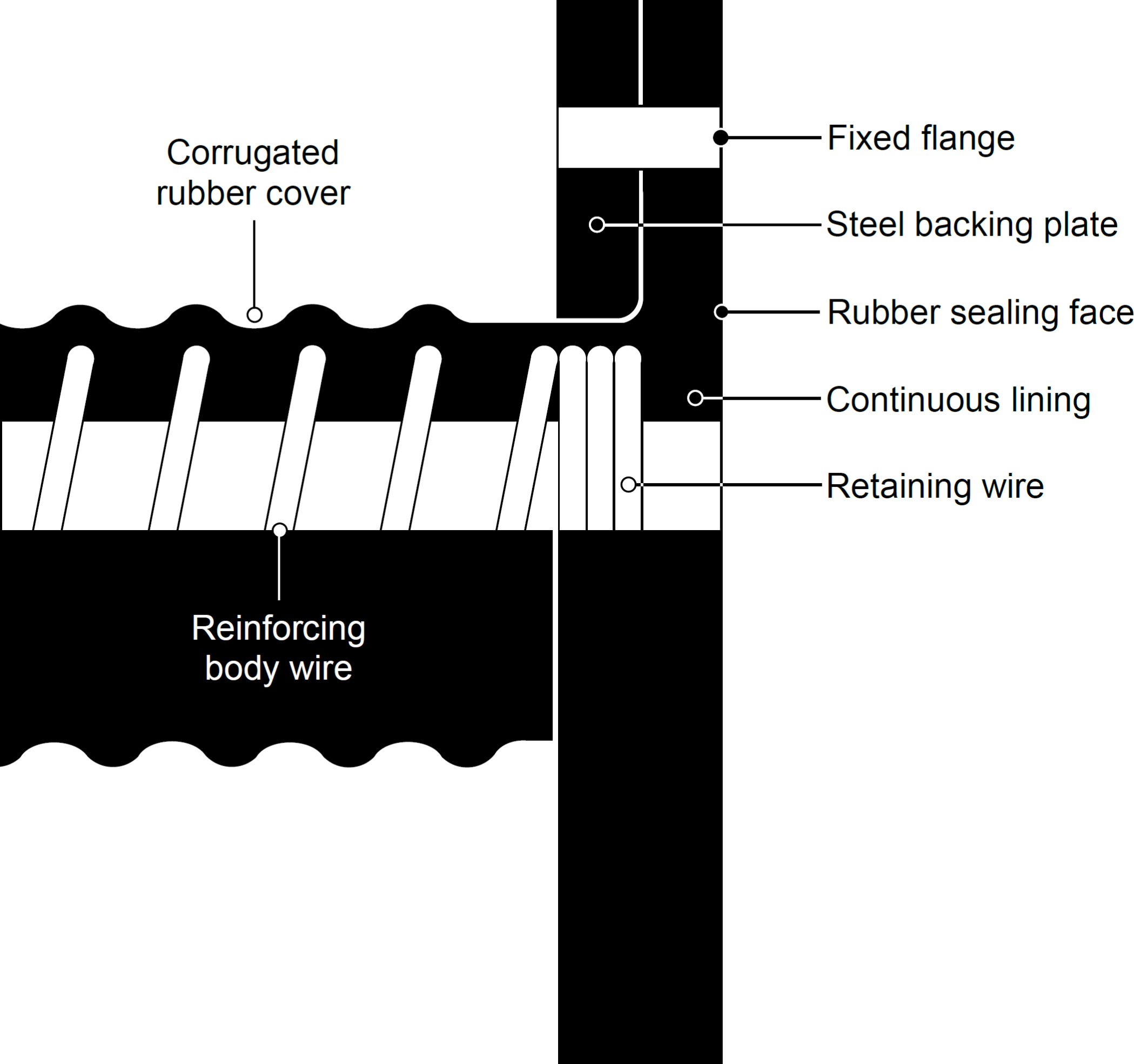

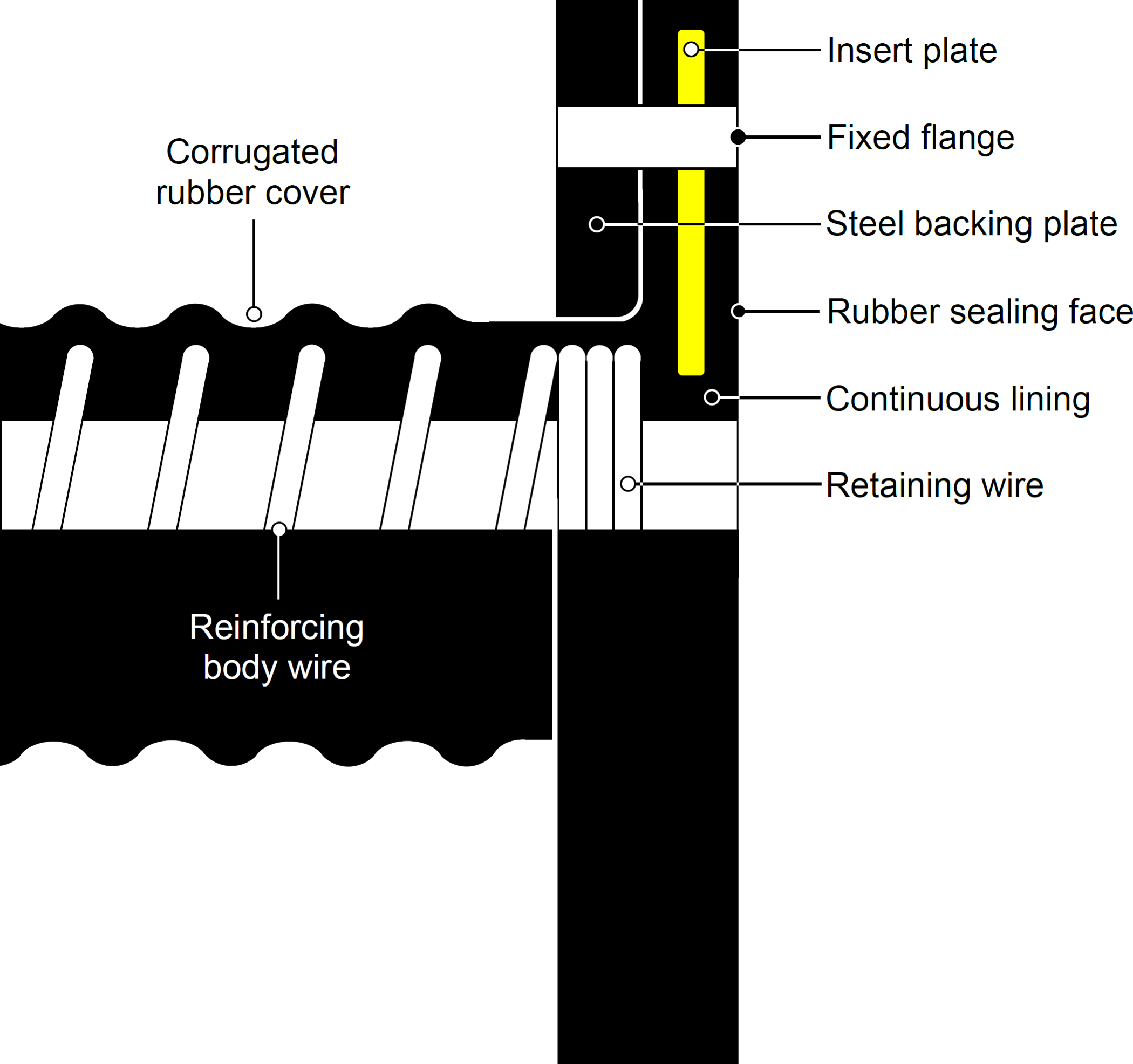

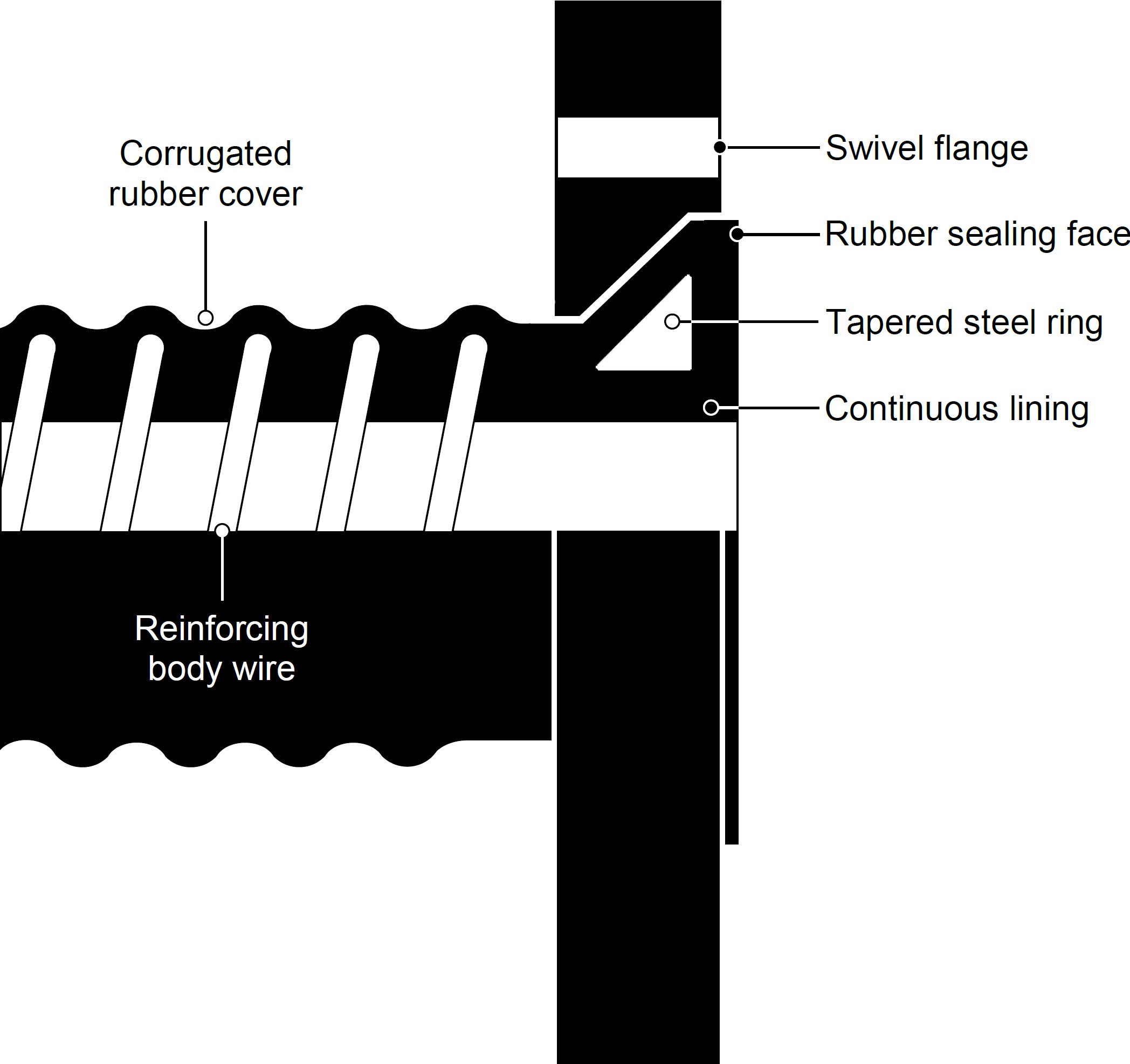

Built-in fitting  Built-in full-bore coupling system for medium to high pressure; non-corrosive and non-abrasive applications. Metal fittings are built into the hose ends during manufacture to form an integral part of the assembly. No external wire or clamps are required as the fitting is chemically-bonded into the hose and mechanically-locked with wire which is embedded in the hose wall between single or double cope rings; securely retaining the fitting in position. Read more.. Built-in rubber lined (fully embedded)  Built-in rubber lined full-bore coupling system for medium to high pressure; corrosive and abrasive applications. Metal fittings are built and vulcanised into the hose ends during manufacture to form an integral part of the assembly. The fitting is encapsulated in rubber thus exhibiting a metal free lining. No external wire or clamps are required as the fitting is chemically bonded and mechanically locked into the hose. An embedded wire retains the fitting firmly in position between single or double cope rings. This system can be designed for the smallest possible pitch circle diameters and is recommended for very heavy-duty applications. Read more.. Integral fixed flange  Integral full-bore coupling system for low to medium pressure; corrosive and abrasive applications. Reinforcing tyre cord plies, encapsulated in rubber continue at right angles against the hose body into a flange. A steel backing plate supports the flange. Elimination of a conventional hose tail allows the hose to begin flexing immediately behind the flange; which is useful for applications requiring a tight bend radius and a more uniform curvature. The backing plate is vulcanised to the rubber and fabric flange; creating a one-piece unit. This system eliminates the necessity of a gasket yet provides a fluid tight seal. The system can be incorporated into any hose type where a smooth uninterrupted through-bore is required. A rubber lining end-to-end ensures that the conveyant has no contact with metal parts. Read more.. Double-action integral fixed flange  Double-action flange is a further development of the integral flange. This system incorporates an additional embedded steel insert plate within the flange structure. This resolves many of the problems associated with pressure pulsation and/or end load/stretch. This system reduces flange bending and loss of sealing at higher pressures especially on flange drillings with a wide pitch circle diameter. Read more.. Beaded end swivel flange  Beaded end full-bore coupling system for medium to high pressure; corrosive and abrasive applications. A steel 'wedge' section ring is fully encapsulated in rubber and fabric to create a bead. A one-piece rotatable flange sits on the body of the hose against and on top of this bead. Elimination of a conventional hose tail allows the hose to begin flexing immediately behind the flange. This is useful for short hoses requiring a tight bend radius and a more uniform curvature. A beaded end is capable of significant end-loading. Read more.. Internally swaged Full-bore coupling system for medium to high pressure; non-corrosive and non-abrasive applications. Modern industrial applications frequently require increasingly high operating pressures. In order to comply with this, swaging techniques have been developed for hose sizes beyond those commonly found in hydraulic systems. Internal swaging provides a full-flow internal diameter free from steps at the hose tail. A process by which the embedding wire is terminated a set distance from the hose ends. Designed to accommodate a hose tail which can be clipped-in, wired-in or strapped-in. Reinforcing fabrics can be protected from corrosion and contamination by rubber 'capping' the ends of the hose; the reinforcement is terminated a nominal distance from the end of the cuff giving the impression of a solid rubber tube. A process by which the hose ends are 'belled' out to create a larger internal diameter than the bore of the hose to facilitate the insertion of fittings where a uninterrupted through-bore assembly is required. Like a plain cuffed end, the embedding wire is terminated a set distance from the hose ends to accommodate a hose tail which can be clipped-in, wired-in or strapped-in. Reinforcing fabrics can be protected from corrosion and contamination by rubber 'capping' the ends of the hose; the reinforcement is terminated a nominal distance from the end of the cuff giving the impression of a solid rubber tube. |